P-Laser's Feasibility test

Inhouse engineering. Custommade.

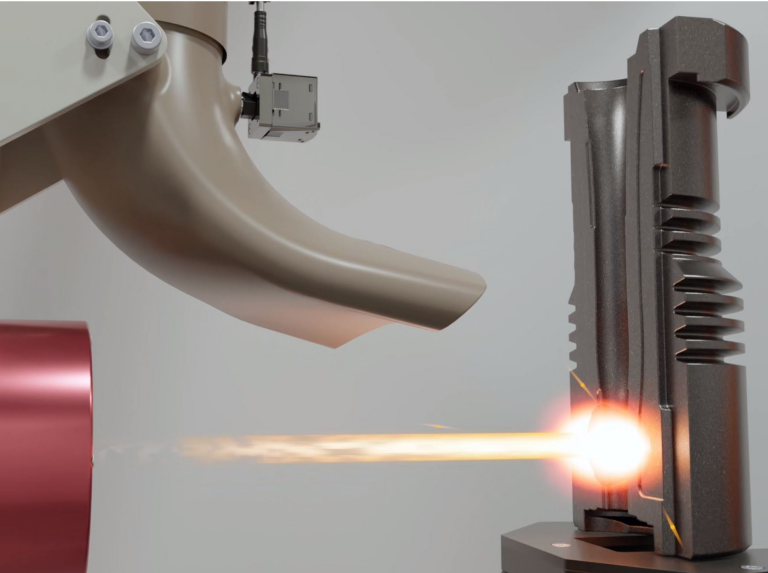

Laser cleaning offers a powerful, precise, and environmentally friendly solution for surface treatment — but every application is unique. That’s why we offer feasibility tests to help you determine whether laser cleaning is the right fit for your specific challenge.

Test Process

Feasibility tests are carried out in our specialized lab using samples provided by the client. We test a variety of laser systems and parameters to determine the optimal configuration. This allows us to identify the best approach to meet your specific requirements — whether that means removing a certain thickness of coating, cleaning oxides without damaging the substrate, achieving a defined surface roughness, or reaching a specific cleaning speed.

Timing and Purpose

Tests are typically performed when a client is exploring laser cleaning as a potential solution. As the technology is still relatively new in many industries, these tests provide a clear, evidence-based understanding of what laser cleaning can deliver in your specific application.

The primary goal is to determine whether your technical and quality requirements can be met with laser cleaning. We also gather key information on the required laser parameters and system configuration, which forms the foundation for technical proposals and budget estimates.

After Testing

Following the tests, you receive a comprehensive report detailing the results, recommended parameters, and observed cleaning performance. This report helps you evaluate the viability of laser cleaning for your needs. If the results meet your expectations, we then look at how the laser solution can be integrated into your production process and provide you with a tailored quotation.

Test Capabilities

To ensure every feasibility test delivers meaningful, production-relevant results, our lab is equipped with a broad range of advanced tools and systems:

- Robotic Platforms

- ABB IRB 1650

- ABB IRBP-A-750

- Configurable with lasers for realistic simulation of automated cleaning setups

- Scanning Electron Microscope (JEOL 6000 + EDS)

- High-resolution imaging

- Elemental surface analysis (oxides, organics, inorganics)

- 3D Digital Microscope (Full HD Hirox 2000)

- Detailed surface observation

- 3D surface mapping

- Roughness Measurement Tools

- Adhesion Testing Equipment

- Surface Tension Testing

- Salt Contamination Detection